Summer Prep for Natural Ventilation

As the hot weather approaches, it is a good idea to assess your natural ventilation system to ensure you are prepared to handle the heat.

The principles of natural ventilation call for adequate sidewall openings to allow the proper amount of air, propelled by the natural winds, to move through the building. The design rule of thumb is one foot (0.3 metres) of wall opening on each side of the barn for every 10 ft. (3 m) of barn width. With a little help from the wind, this arrangement will move a surprising amount of air through your barn.

For example, a 200-foot-long (60-metre-long) building with a 5-ft. (1.5-m) opening and a 16-kilometreper- hour (10-mile-per-hour) wind will move 880,000 cfm (actual cubic feet per minute) of air. This figure is the approximate equivalent of 35 x 50-inch (127-centimetre) exhaust fans running at full speed. Even with a slower 2 km/hr (1.2 m.p.h.) wind, the air moved is equivalent to 13 x 24-inch (61-cm) exhaust fans.

However, problems can arise on days with high temperatures, high humidity and calm winds. In these situations, we need to give Mother Nature a helping hand.

If no natural wind is present to move the air, we must create a mechanical wind to provide what is referred to as “velocity cooling.” This feeling is created by high-speed air moving over the pigs’ skin.

Velocity cooling is the same sensation we experience when we put our faces in front of a fan on a warm, humid day. Even though the temperature of the air that the fan is moving is hot, it still feels cool because of the speed (velocity).

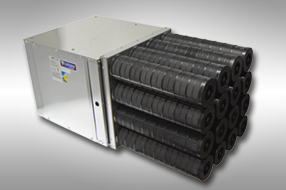

In a barn, this velocity air is created by mounting circulating fans inside the building to move the air around at speeds ranging from 250 to 500 ft. (75 to 150 m) per minute. These fans can be positioned to blow air from one side of the structure to the other through the pens, or in a racetrack design.

In the latter configuration, two rows of fans run the length of the barn. One row blows air in one direction and the other row blows air in the opposite direction. This setup creates an air pattern like a racetrack.

The layout of the fans will be determined by the pen layout and whether the stall walls are solid or made with spindle penning. If the pens have solid walls, then directing the air from side to side is preferable to avoid blockage of air movement. With spindle penning, end-to-end air movement can be achieved.

For year-round ventilation, using a variable-speed circulating fan enables you to circulate heat at slow speeds during the winter, eliminating hot spots near heaters.

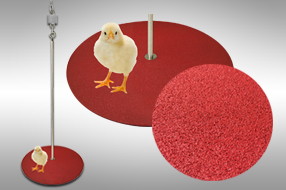

The other cooling option available for hot environments is a sprinkler system, which creates an evaporative cooling effect. This system uses larger droplets of water instead of a highpressure mist of water. The system first sprays water onto the pigs’ skin. The air movement created by the circulating fans evaporates the water droplets, which creates a cooling sensation.

Essentially, this process is like what happens when humans perspire. When we sweat in hot temperatures and a breeze evaporates these sweat droplets, it creates the perception of cooling.

In hot, humid climates, heavier droplets of water work better than a mist. A light mist can hang in the air and add to the humidity levels in thebarn, which may lead to respiratory issues in pigs.

The sprinkler system also has the benefit of wetting the barn down thoroughly prior to cleaning and disinfecting.

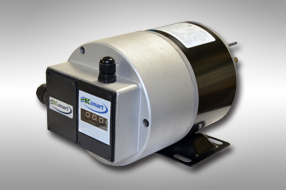

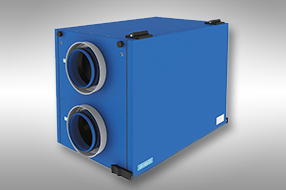

As with all ventilation designs, this type of system requires a controller that can integrate the operation of both your natural and power summer ventilation. Some days, you will need circulating fans and/or the sprinkler system running during the daytime but not overnight. You must have a controller that will make these changes for you based on the interior temperature of your building.

If you already have these systems in place, now is an ideal time time to dust off your fan motors and blades. Check the water filters and nozzles on your sprinkler system. Make sure everything is operating at peak efficiency.

By completing this maintenance, you will ensure that your pigs remain cool, comfortable and healthy during the next heat wave.

As seen in June 2020 edition of Better Pork.