Ventilation Options for your Pig Barn

Over the last 25 years, natural ventilation systems have become commonplace in large group finishing hog facilities.

Insulated sidewall curtains or solid insulated sliding panels, combined with insulated ridge-mounted chimneys, were the hallmarks of a quality low-cost natural ventilation system. In an all-in-all-out system during cold weather conditions, an additional heat source is commonly required in barns full of 55-pound (25-kilogram) pigs.

In a flow-through system, the heat generated by the mixture of heavier weight hogs renders this additional source unnecessary. The extra advantage of this type of system is that it does not require mechanical ventilation for the under-floor manure pit in total slat barn designs. The natural ventilation typically maintains a neutral static pressure within the room. As a result, the manure gas remains below floor level since it is heavier than air.

In the late 1990s and early 2000s, companies introduced the concept of a dual or hybrid ventilation system to the industry.

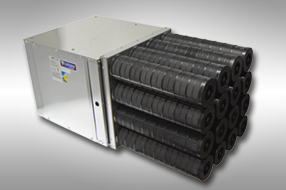

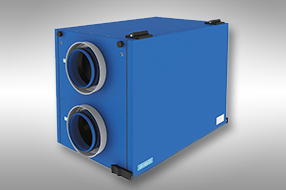

This system combines mechanical fans, either sidewall mounted or in chimneys through the ridge, along with fresh air intakes mounted on the ceiling. These intakes draw fresh air from the attic through soffit openings. This system also uses sidewall curtains or panels typical with natural ventilation.

What are the benefits to this system? The power ventilation part of the system used in cold weather conditions provides tighter temperature control than can be achieved with an all-natural system. For example, in a natural ventilation system, if the barn is full of market-weight pigs in the winter, the producer controller may have to slightly open one or both of the sidewalls to dissipate the heat generated by the animals. If this situation occurs in below-freezing outside temperatures, it can cause the interior temperature to become erratic.

When this temperature fluctuation happens, producers using natural ventilation will occasionally experience a temporary increase in feed consumption as the animals eat more to replace lost body heat. Typically, farmers think this additional feed cost is not prohibitive.

As the economics of hog production became more complex, however, many producers not willing to absorb these extra costs discovered that a dual ventilation system was the most effective way to minimize this increase in feed consumption.

Companies can design dual ventilation systems using two principles. The first design uses a natural ventilation system with power ventilation for cold weather. The second design entails a power ventilation system with sidewall openings for hot weather.

In the first case, you would typically size the power ventilation portion of the system for approximately 25 per cent of the total ventilation requirement. In the second scenario, the power ventilation would have a much larger capacity, usually at least 50 per cent.

Producers can operate both designs effectively, but initial equipment and operating costs can be a deciding factor as to which you option you select. Proponents of the first design appreciate the benefits of natural ventilation and want to use that portion of the system as much as possible throughout the year. Either way, both systems will provide tighter ventilation control than natural ventilation in cold weather.

The other factor to consider when choosing between natural and dual ventilation is the automation control required. In a natural ventilation system, producers generally use a controller that opens and closes each sidewall opening based on an internal temperature sensor.

The producer typically manually controls the dampers in the ridge chimneys, since they tend to be positioned seasonally and require only a temporary adjustment to deal with extreme cold. In some situations, the dampers can remain fully open throughout the year, depending on the rotation of the hogs and the weather. The controller for this type of system will have a contact and setting that will automatically turn the heater(s) on and off as required.

In a dual ventilation system, producers will require a more sophisticated control system. The controller will automatically speed up and slow down the exhaust fans on a variable speed basis and, depending on the size of the building, will also operate the fans in more than one stage to provide a smooth increase in the exhaust capacity.

At the same time, the fresh air intakes are automatically opened and closed to provide an equal amount of fresh air to match what the fans are exhausting. Once a set temperature is reached within the room, the system will switch over to natural ventilation and begin to open the sidewalls as required.

At certain times of the year, typically in the spring and fall, the system will run on a natural basis during the day but switch to the power portion overnight when the outside temperature drops.

Once the system is running as a natural system 24 hours a day, the producer typically moves the ceiling inlets to the closed position to keep hot air from entering from the attic. The decision as to whether to continue running the fans is based on operator preference.

Regardless of your preference, a properly designed natural or dual ventilation system will provide you with the optimal environment required for both healthy pigs and profitable production.

As seen in Feb 2020 edition of Better Pork.