Get Natural Ventilation Ready for Warmer Days Ahead

Spring is upon us. It is time for your natural ventilation system to get back to work. This is a season that can experience significant fluctuations in outside temperature during any given 24-hour period, which means your sidewall curtains or panels will be moving more frequently than they have been through the winter months.

Once it starts to warm up outside, it is a good idea to manually run all of your curtains fully open and fully closed. Throughout this process, keep a close eye on the operating hardware for anything that is catching, frayed or broken. When the curtains or panels are closed, do a walk around to inspect your fabric for wear points, holes or tears. If you need to have your fabric replaced, spring is definitely the time to do it. There is generally more time available to do this work early in the season than in late fall when companies are scrambling to close new barns in to protect them from the cold.

If you have electric drives with gearboxes or universal joints, now is also the time to inspect all of the grease nipples and check them for any frayed or damaged wiring.

If you are currently running your thermostat for winter operation, typically at 2°C to 3°C, you will need to start moving that set point up as the weather gets warmer. By setting your thermostat higher, you will avoid situations in which your curtains remain open for an extended period while the external temperature fluctuates dramatically. For example, consider a day in which the outside temperature rises from 5°C in the morning to 18°C at noon and then back to 5°C overnight. If your thermostat is set at 5°C, then your curtains will have stayed fully open all day while the inside barn temperature has changed by 13°C. Such a variation in temperature is not good for the health of your cows. In this instance, a thermostat with a set point of 12°C would have ensured the curtains raised and lowered accordingly to maintain a more comfortable and stable inside environment.

If you are running a manually operated curtain system, now might be the time to consider investing in temperature-controlled automation. Spring and fall are the times of year when this investment will really pay off due to the significant temperature changes that are often very difficult to keep up with manually. If automation isn’t in this years’ budget, then consider purchasing a large round dial thermometer and hanging it from the ceiling directly over a cattle area. With this tool, you can monitor the actual temperature in the livestock area and make the necessary manual adjustments to maintain a consistent environment. Adjusting your curtains based on whether you feel hot or cold is a sure way to get it wrong because your cows are feeling the temperature much differently than you are. If you’re unsure what the optimal temperature should be, it is always best to make the barn slightly cooler rather than warmer. Remember, fresh air is best for you and your cows!

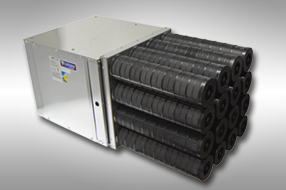

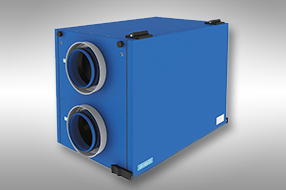

Regardless of which type of summer ventilation – tunnel ventilation, interior circulating fans or sprinkler systems – you are operating, spring is the time to do tests and make sure that nothing has stopped working over the winter months. For fans, be sure to inspect all the motor belts to ensure they have the proper tension and are not frayed. A loose belt can prevent your fan blade from generating the required exhaust and air velocity, even while it continues to use the same amount of electricity.

Not only are these checks more pleasant for you to perform on a nice 16°C spring day, but having the foresight to examine your ventilation equipment early means you have time to fix any problems before the extreme temperatures hit. This also ensures that your cows will remain cool, comfortable and healthy during the next heat wave. Therefore it is time well spent.

As seen in May 2020 edition of Progressive Dairy Canada.