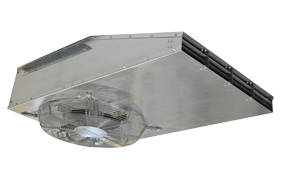

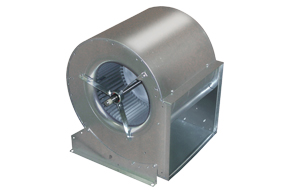

IDB Series Forward Curved Inline Duct Blowers

SKU#:

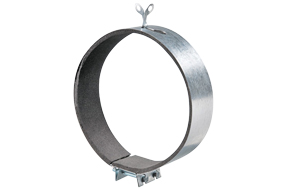

IDB SERIES

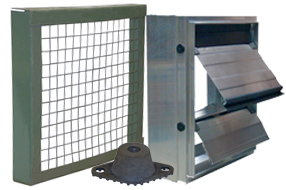

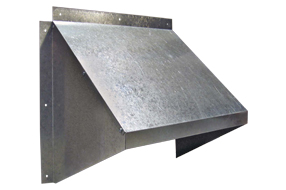

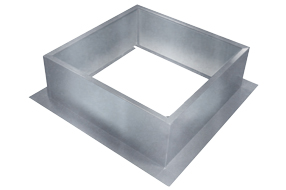

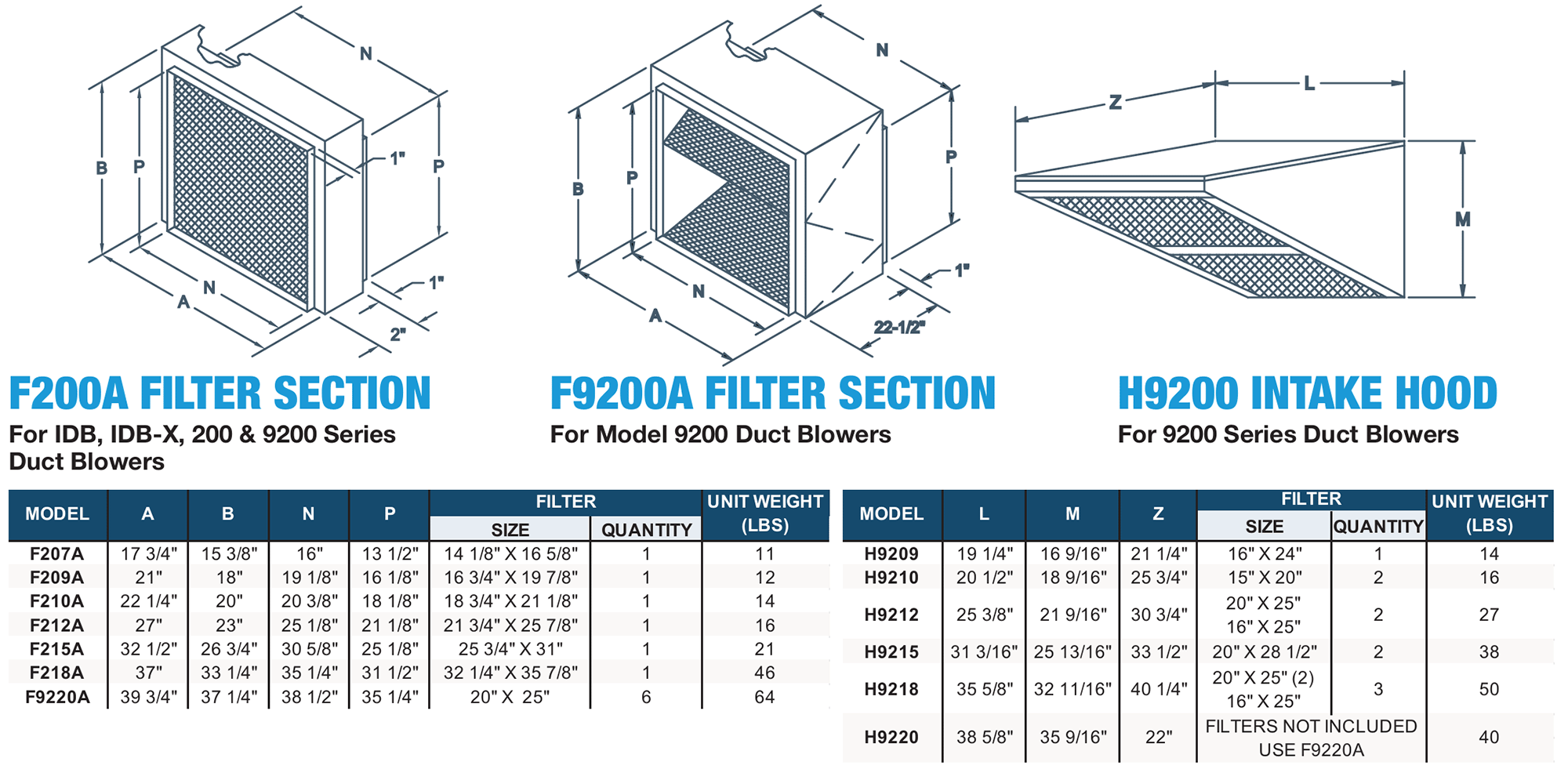

Model IDB is a belt drive duct fan designed for interior supply, exhaust, make up air, or ducted return applications. Units feature forward-curved wheel, and galvanized steel housing. CFM's up to 5700. Insulated options as well as filters, intake hoods and hot or chilled water coils for many different applications. Twin options available.