VENTILATING YOUR FABRIC STRUCTURE FOR HEALTHY, COMFORTABLE COWS

Steel frame, fabric covered buildings used for commodity and equipment storage have been common in the agricultural industry for decades. In the 1990’s, manufacturers of these buildings started to promote them for livestock housing with the primary advantages being cost and speed of construction. This change in application made it necessary to include ventilation systems in the design to ensure a healthy environment for the animals.

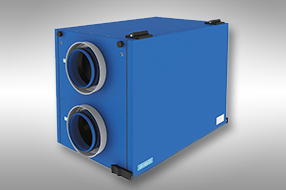

The fact that these types of structures are completely non-insulated and have a very large interior air space means that natural ventilation is the ideal choice for air movement. The basic design is very similar to livestock facilities that are naturally ventilated with curtain systems along the sidewalls and a ridge exhaust for the cold weather conditions.

For fabric based buildings it is critical that the sidewall curtains be equipped with electric drives and operated with a thermostat controller. The reason for this is due to the fabric liner causing the interior temperature to rise and fall very rapidly during a 24 hour period. If your curtains are not moving automatically in response to these changes, there could be significant fluctuations in the inside temperature, leading to an unhealthy environment for your cows, especially younger calves.

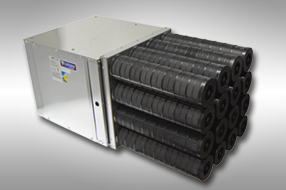

The lack of insulation in these buildings also means that everything that is operating in the facility needs to be designed and equipped to operate in below freezing conditions. Ridge ventilation becomes extremely important since it ensures that all of the warm, moist heat being generated by the animals is removed during the winter months. Open ridge and overshot ridge systems can also be used, but in my experience, chimney systems have proven to be the most effective method of achieving optimal winter ventilation. Once the outside temperature drops below that of the interior, the chimney starts to draw air from the inside of the building. As the temperature difference increases, the draw of the chimney gets stronger and removes larger amounts of heat, moisture and contaminants.

If the ridge exhaust is restricted or not available to keep inside temperatures up, the warm, moist air that is trapped will create condensation on the interior surfaces of the liner, which will become ice in winter conditions. In extreme cases it will literally be raining inside due to the dripping condensation. You could also see an accumulation of several inches of ice buildup that will again create running water when it melts. At certain times throughout the year you may also experience a freeze and thaw cycle during a 24 hour period.

With proper ventilation, the majority of these fabric structures being used for livestock can operate successfully during cold with an inside temperature approximately 10 degrees higher than outside. That means that if it is -15 degrees Celcius outside, you should have your thermostat set to maintain an inside temperature of -5 degrees Celcius.

Conversely, the lack of insulation will tend to create higher interior temperatures in the summer months than what you would typically see in an insulated building. Natural wind effect from the sidewall curtain openings will help to control the heat buildup, but on days where you have high temperatures, high humidity and minimal wind, the addition of fan powered air movement for velocity cooling can be very effective. This can be achieved by using high speed circulating fans or the large diameter high velocity, low speed (HVLS) ceiling fans. An additional advantage of the HVLS fans is that they can be operated at a slow speed - approximately 20% - in reverse in the cold weather. This will move air upwards and recirculate it along the interior of the roof liner which helps reduce condensation in winter conditions.

A fabric covered structure can be an economical and effective choice for a dairy facility but some consideration must first be given to proper ventilation design to create the healthiest environment for your animals. As always, it is beneficial to consult with your local ventilation specialists while still in the planning stages. Their knowledge and experience will ensure you have all of the necessary tools and equipment to ensure a successful outcome on your next project.

As seen on ProgressiveDairy.com