Managing Natural Ventilation in your Calf Barn

Many dairy operators have chosen to relocate their calves from outdoor hutches to indoor housing. This shift offers more convenient management and allows for layouts suitable for group housing and automated feeding systems.

A significant number of these structures have been equipped with natural ventilation systems, typically involving a combination of curtain or sliding panel systems on wall openings and ridge systems for cold-weather air exchange.

Common ridge systems include the open ridge, overshot ridge and chimneys. The chimney system offers the advantage of positive air exhaust along with adjustable dampers for enhanced temperature control.

Given the sensitivity of these animals, ensuring the right environmental conditions is a top priority to prevent health issues.

A critical aspect to manage is the interior temperature. It's not necessarily about maintaining warmth during winter, since we know that calves have done well in outdoor hutches. The concern lies in dealing with significant temperature fluctuations within a 24-hour period, which are common in many regions during spring and fall. Furthermore, non-insulated structures can rapidly heat up and cool down during these seasons. The most effective way to regulate these temperature changes is by operating the sidewall system with electric drives controlled by a thermostat. This system will automatically open and close the sidewalls to maintain the desired indoor temperature, adjusting the curtains based on internal temperature, external temperature, wind speed and direction, and the presence of rain.

Minimizing drafts in a natural ventilation system is also crucial. Designing pens or stalls with a walkway around the perimeter helps prevent cold air from entering sidewall openings and dropping directly on the animals. Adding a windbreak mesh to the top 25% of the sidewall opening is also beneficial, enabling air to enter the room while reducing the speed that could otherwise create drafts. As mentioned earlier, integrating a weather station input into your controller allows individual curtains or panels to open and close based on wind speed against specific openings during colder weather.

The actual interior temperature will vary depending on the type of structure, whether it is insulated, non-insulated or a fabric structure. In general, maintaining a colder interior temperature during winter is favorable, as it increases air exchange through the ridge system, helping control humidity and ammonia levels. Remember that calves are not bothered by the cold, so cold and dry is better than warm and damp.

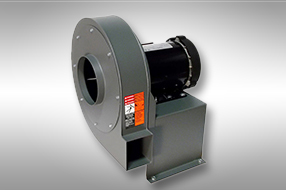

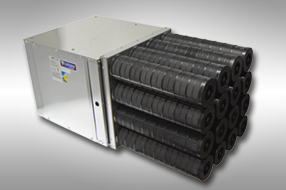

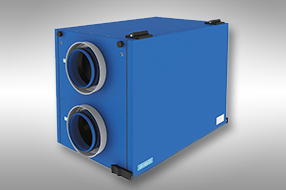

Incorporating natural ventilation into a calf barn also provides an opportunity to add a positive-pressure tube system. This system allows you to introduce exterior air into the room during cold weather using a distribution tube that controls both airspeed and pattern, thus preventing drafts on the animals. This also pressurizes the interior and enhances the exhaust capacity of your ridge system, improving air quality. Careful consideration of engineering details, such as the size and pattern of holes in the tube and fan capacity, is crucial for proper system operation.

Another potential addition to your system is interior circulating fans. These fans can run at low speeds during colder weather to eliminate stale air spots and operate at full speed in hot weather, creating velocity cooling for the animals.

By prioritizing proper ventilation system design and operation, you can successfully house your calves indoors without compromising their health. When designing your livestock facility, consulting experienced ventilation designers in your area is always a valuable step.

As seen in Jan 2024 edition of Progressive Dairy USA.