Sidewall Options for Swine Ventilation

Natural and dual ventilation have increasingly become the ventilation systems of choice for finishing and dry sow/breeding facilities. Once you have decided on your preferred system, options for the style and product used on the sidewalls need to be considered.

Analysis of multi-layer insulated sidewall curtains

These types of curtains typically provide a sidewall system with an R2 to R3 insulation value. The material drops down from the top of the opening on a cable and pulley system and folds at the bottom.

One of the advantages of this type of system is the light weight, which allows for larger openings and longer section lengths per actuator. This is a definite economic advantage on longer buildings. The overall cost of this type of system is comparatively lower than other options, improving the project economics. If properly maintained, this type of fabric can give you an eight-to-10-year lifespan with the hardware lasting through two fabric changes.

Multi-layer insulated sidewall curtains do present some challenges, though. During hot weather, the fabric is folded up at the bottom of the opening, which can allow rainwater to collect in the folds. If left there, the water will weigh down the fabric and create abrasion on the hardware which will shorten the lifespan of the product.

This standing water can also create mould and mildew that causes discolouration and deterioration of the material. The folds of material are also an ideal spot for mice to nest and they will spend their time chewing holes in the outside liner, giving your curtain system the “swiss cheese” effect when you close it up in colder weather.

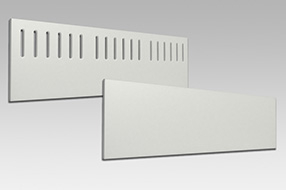

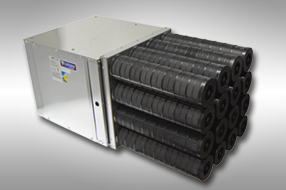

Solid insulated sliding panels

These panels are typically manufactured from a rigid fibreglass-reinforced plastic material, which typically provides an R6 to R8 insulation value. The panels slide down the wall on metal guideposts using a cable and pulley system. This type of product has a seal system that when closed, prevents cold air from leaking around the panels and creating drafts.

Solid insulated sliding panels provide a longer lifespan than insulated curtains along with a higher R value. However, you are restricted in the size of the opening you can have, as the panels require enough wall below the opening to slide past the bottom. When closed, these panels do not provide any natural light, although optional thermal glass windows can be added if required.

Due to the weight of this product, you are restricted in the maximum length of the sections per actuator which, along with the material costs, make this system a higher-priced option.

Maintenance required for this type of system should include regular inspection of the operating hardware to identify any broken or worn components. This inspection is important because a hardware failure, especially in cold weather, will cause the panel to drop to the bottom. This often damages the panel and creates a dangerous drop in temperature inside your facility.

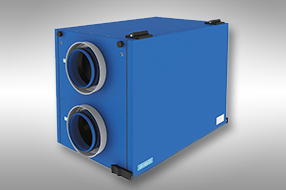

Polycarbonate sliding panels

This type of panel system has become more popular over the last few years, especially for dry sow and breeding barns. Its main advantage is that it offers approximately 95 per cent light transmission when fully closed. This abundance of natural light in cold weather creates a pleasant atmosphere for both animals and operators.

The R value on the polycarbonate is in the range of R3 and these panel systems also have a seal system to stop drafts. They operate in the same way as the insulated panel systems and have a lifespan of more than 20 years. So, even though the initial cost is higher than that of an insulated curtain, its longevity offsets that higher cost in the long run.

Other considerations

When reviewing the pros and cons of these different types of systems, don’t get too hung up on the R value. Experience has shown that much of the heat loss in these types of facilities is upward through the ceiling versus outward through the sidewalls.

In addition, you will discover that the amount of time during the year when all of your sidewall openings are completely closed is not as much as you might think.

Remember, animals generate heat containing ammonia, moisture and contaminants that must be exchanged with fresh air to maintain a proper environment.

All of these systems will work if they are part of a properly designed natural or dual ventilation system. Ultimately, your final decision will come down to your personal preferences and budget.

As always, you will be well served to consult with an experienced ventilation system designer to make sure that the final ventilation design meets all of the present and long-term needs of your facility.

As seen in June 2021 edition of Better Pork.